Increase in the Volumetric Occupancy Ratio and skin effect

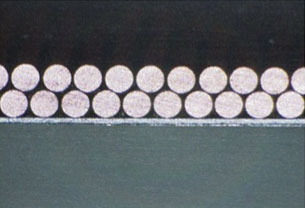

An increase in the volumetric occupancy ratio means that the self resonance of the wound coil decreases. Compared to round wire, both ribbon and square wire have a 27% higher voumetric occupancy ratio.

The tendency for current to flow round the surface of a wire at high frequencies is known as the skin effect, and compared with a round wire of same size, the square wire is greatly superior.

Greater heat Dissipation

COMPERISON WITH ROUND WIRE

Compared with a coil wound with the same size of round wire, a square wire coil has a 15-20% lower DCR, resulting in a power increase. A lower DCR also results in less heat being produced, meaning that less energy is required, a factor that has obvious environmental benefits in areas such as combatting global warming etc.

When the same DCR as a round wire coil is required, a smaller size square wire should be used. For example, compared with a round wire of 0.45mm a square wire of size 0.40m x 0.40mm gives the same DCR, meaning that both a decrease in the size of the coil and surrounding parts is possible, resulting in a decrease in size and cost of the whole set.

Decreasing at 27℃ even if the number of turns increase 100.(Resistance is an approximate value).